Why Precision, Planning, and Expertise in Architectural Panel Systems Matter More Than Most People Realize

A building’s exterior does far more than define its appearance. It protects structural components, controls moisture and air movement, supports long-term durability, and directly influences operational performance for decades. When panel systems are designed and installed correctly, they become a high-performing layer of defense that enhances the building’s lifespan, efficiency, and value. When installation is rushed or poorly executed, those same systems can become a source of recurring maintenance issues, water intrusion, and premature material failure.

This is why panel system installation in Washington requires a level of technical precision and regional expertise that goes beyond basic construction practices. From coastal moisture exposure to temperature fluctuations and seismic considerations, buildings in this region demand carefully engineered envelope solutions. In this article, we explore how proper panel system installation impacts long-term building performance, what separates quality installations from problematic ones, and why working with an experienced architectural sheet metal contractor like Bassett Construction makes a measurable difference.

Understanding Panel System Installation and Its Role in Building Performance

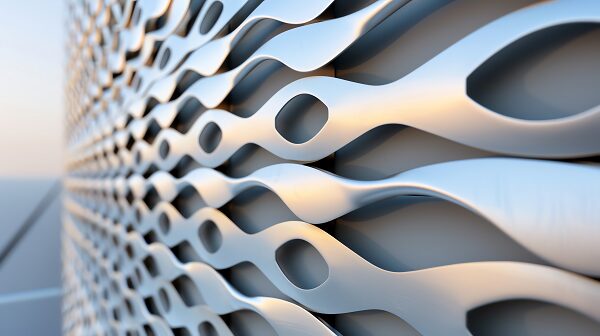

Panel systems are a core component of modern architectural design. They serve both functional and aesthetic purposes, forming part of the building envelope that controls how a structure interacts with its environment. Proper panel system installation in Washington involves far more than attaching materials to a façade. It is a coordinated process that blends design intent, material science, engineering principles, and field execution.

What Panel Systems Actually Do

Architectural panel systems, including insulated metal panels, composite wall panels, single skin metal panels, and custom-fabricated facades, create a continuous exterior layer that shields buildings from wind, rain, temperature variation, and physical wear. When installed correctly, these systems help manage moisture, reduce thermal bridging, and maintain consistent performance across the building envelope.

In Washington’s climate, where moisture control is critical, panel systems must be installed with precise detailing around joints, penetrations, transitions, and expansion points. Even minor errors in alignment or fastening can compromise performance over time.

Common Misconceptions About Panel Installation

One of the most common misconceptions is that all panel systems perform the same once installed. In reality, long-term performance depends heavily on installation quality. Materials alone do not guarantee durability. Improper sequencing, inadequate fastening methods, or insufficient coordination with other envelope components can all undermine even the highest-quality panels.

Another misconception is that panel system installation is interchangeable between regions. Panel system installation in Washington must account for regional weather exposure, building codes, and construction practices. What works in a dry climate may fail prematurely in the Pacific Northwest.

Looking for The Best Panel System Installation Company?

Don’t wait—Contact us today to have the best panel system installation service!

Why Proper Panel System Installation Matters Over Time

The impact of installation quality becomes more evident as buildings age. While issues may not appear immediately, improperly installed panel systems often reveal problems within a few years, especially under repeated environmental stress.

Structural Integrity and Longevity

Correct panel system installation supports the long-term structural integrity of the building envelope. Panels must accommodate thermal movement, structural deflection, and wind loads without warping, separating, or placing stress on fasteners. When installation does not allow for proper expansion and contraction, panels can buckle or crack, leading to costly repairs.

Bassett Construction approaches panel system installation with a deep understanding of constructability. This ensures that each system functions as intended over the full lifecycle of the building, not just at project completion.

Moisture Management and Weather Resistance

Moisture intrusion is one of the most damaging issues for commercial and industrial buildings. Water that enters behind panel systems can compromise insulation, corrode metal components, and affect interior finishes. Proper panel system installation in Washington prioritizes water management through precise detailing, correct flashing integration, and disciplined sequencing.

Building envelope consultants play a critical role here. By evaluating how panel systems interface with other envelope elements, Bassett Construction helps prevent hidden vulnerabilities that often go unnoticed until damage occurs.

Energy and Thermal Performance

While architectural panel systems are not energy systems themselves, they directly influence thermal consistency and air control within a building. Poorly installed panels can create gaps and thermal bridges that reduce overall performance. Over time, these inefficiencies contribute to inconsistent interior conditions and increased strain on building systems.

Proper installation ensures continuity across the envelope, supporting stable interior environments and protecting insulation layers from degradation.

Guidelines for Installing High-Performance Panel Systems Effectively

Achieving long-term performance requires a disciplined, methodical approach that begins well before installation day. Panel system installation in Washington benefits most from early planning, collaboration, and experienced oversight.

Integrating Design and Installation Early

Successful projects begin with alignment between architectural metal design and installation planning. When panel systems are designed with constructability in mind, installation becomes more efficient and accurate. Bassett Construction frequently supports projects through design assist and value engineering services to ensure panel systems can be installed without compromising performance or aesthetics.

Early collaboration allows potential challenges to be identified before materials are fabricated, reducing costly field adjustments and delays.

Precision in Fabrication and Custom Solutions

Custom-fabricated facades require exceptional accuracy. Even small dimensional inconsistencies can create installation challenges that affect panel alignment and joint integrity. By combining architectural metal design expertise with installation experience, Bassett Construction ensures that custom elements integrate seamlessly into the building envelope.

This level of coordination is particularly important for complex or unconventional projects where standard solutions do not apply.

Disciplined Installation Practices

Proper panel system installation is not rushed work. It requires experienced crews who understand sequencing, fastening requirements, and tolerance management. Each panel must be installed in a way that respects the system’s design intent while accounting for real-world conditions.

In some cases, a short, focused checklist supports clarity during installation:

- Verification of substrate conditions before installation begins

- Precise alignment and fastening according to manufacturer and design specifications

- Careful detailing at transitions, penetrations, and expansion points

These practices help ensure consistency across the entire façade.

Ongoing Quality Oversight

Management plays a critical role in long-term success. Panel system installation in Washington often involves coordination with multiple trades and stakeholders. Bassett Construction manages every phase of the process, maintaining quality control and schedule discipline while adapting to site-specific challenges.

This proactive oversight reduces errors, improves accountability, and ensures the finished system performs as intended.

Why Expert Panel System Installation Is a Long-Term Investment

Proper panel system installation is not a cosmetic decision. It is a long-term investment in building performance, durability, and reliability. From moisture control and structural stability to aesthetic longevity, the quality of installation directly affects how a building functions for decades.

For projects requiring expert panel system installation in Washington, Bassett Construction brings architectural metal design expertise, building envelope consulting, custom-fabricated facades, and disciplined installation practices together under one experienced team. Contact Bassett Construction today to discuss how thoughtful planning and precision installation can protect and elevate your building’s performance well into the future.

Other Construction Services We provide

- Custom Fabricated Facades in Washington: We design and fabricate unique, custom facades that transform a building’s exterior into a work of art, combining sleek design with structural integrity.

- Architectural Metal Design in Washington: We specialize in creating innovative and visually stunning metal enclosures and features that elevate the aesthetics and functionality of your building.

- Building Envelope Consultants in Washington: Our expert team provides comprehensive guidance and solutions for your building’s exterior, ensuring superior performance, durability, and weatherproofing of critical structures.

Looking for The Best Panel System Installation Company?

Don’t wait—Contact us today to have the best panel system installation service!

FAQs About Panel System Installation in Washington

Connect With Us

Phone: (360) 718-8640

Location: 9210 NE 62nd Ave Bldg B, Suite 210, Vancouver, WA 98665

source https://www.bassettusa.com/blog/how-does-proper-panel-system-installation-impact-long-term-building-performance/